Insulated Prefabricated Building with Ce Certification

Información básica

Modelo: KXD-004

Descripción del producto

Model NO.: KXD-004 Customized: Customized Warranty: 30 Year Limited Warranty Member of Engineering Team: 20 Life Cycle: 50 Years Customer Service: Aftersale Service Engineering Tools: Autocad Transport Package: Seaworthy Package for EPS Sandwich Panel Origin: Qingdao, China Certification: BV, ISO, SGS Size: According to Customers′ Requirement Color Reference: Ral Quality Control: Daily Construction Period: 60 Days Project Management: Turnkey Solution Trademark: KXD Specification: ISO, SGS, BV HS Code: 7210900000 Insulated Prefabricated Building with CE Certification

Product Brief

Prefabricated building,which is also called Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for modular house solution

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

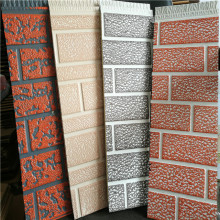

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

Specifications

solution

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

Specifications

solution

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

Specifications

Product Brief

Prefabricated building,which is also called Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for Modular buildings and modular houses/homes are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. "Modular" is a method of construction differing from other methods (e.g. "stick-built" and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building's foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

Modular buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

1.Technical Data-Standard containerized modules for modular house solution

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

|

(1) Simple Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet | |

| Door | Simple steel rolling shutter (within 10m2) | |

| Window | Very few | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Africa, Middle-East, South America (no snow, wind load below 0.4kn/m2) | |

|

(2) Standard Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 24m, H -lower than 8m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door(within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Snow loading below 0.5kn,wind loading below 0.5kn/m2 | |

|

3) Coastal (high wind speed) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Coastal areas (snow loading below 0.7kn, wind load below 1.2kn/m2) | |

|

(4) Cold Region (heavy snow) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | EPS/rock wool/PU sandwich board |

| Wall | EPS/rock wool/PU sandwich board | |

| Door | PU foamed rolling door | |

| Window | Alu. Alloy, Hollow glass | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Cold regions such as Norway, Russian, North Canada, Finland, Iceland, Greenland, Sweden, etc. (snow loads below 3kn, wind load below 1KN/M2) | |

|

(5) Steel Structure Workshop with Crane (5T, 10T, 20T) |

||

| Main structure | Single span: L -shorter than 20m, H -lower than 10m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Snow 0.5kn, wind load below 0.5kn/m2 | |

| Name | steel structure hangar |

| Standard | GB |

| Main Material | |

| Main frame | Q 235 &Q345 |

| Bracing | Angel and round pipe |

| Purlin | C or Z section steel |

| Connection | Normal bolts and High strength bolt |

| Roof panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Wall panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Accessories | Skylight belts, Ventilators, Down pipe, Out gutter |

| Windows | Aluminum window/PVC sliding window |

| Doors | Sliding door;Rolling up door;Folding tip-up door;PVC door |

| Surface | Hot dip galvanize or Painted |

| Packing | Main frame packed in 40FT container, maintenance packed in 40HQ container |

| Main market | North America, South America, Eastern Europe, Southeast Asia, |

| Africa, Oceania, Mid East, Eastern Asia, Western Europe | |

|

Name |

Steel Structural |

|

|

Dimensions |

Length |

H beam:4000-15000mm |

|

Thickness: |

web plate:6-32mm wing plate:6-40mm |

|

|

Height |

200-1200mm |

|

|

Color |

according to customers |

|

|

|

|

|

|

Advantages |

1. design according to customers' requirements |

|

|

2. manufacture under complete quality control system---ISO9001 |

||

|

3. Fast construction and easy installation . |

||

|

4. installation with instruction of experienced engineers |

||

|

5. Hight quality and low-price . |

||

|

6. Wide span , Flexible design , Long using life |

||

|

7.Others: environmental protection, stable structure, earthquake resistance, water proofing, and energy conserving. |

||

|

Main components |

Main frame |

H beam |

|

Purlin |

C or Z section steel purlin |

|

|

Brace |

Anchor, ordinary, high strength bolt |

|

|

Bolt |

Sandwich panel or steel plate |

|

|

Roof &wall |

PVC or aluminum alloy door |

|

|

Door |

Sliding or rolling door |

|

|

Insulation panel |

EPS,XPS,Rock wool , PU sandwich |

|

|

Material |

Q235,Q345 China standard steel |

|

|

Sheet |

0.5mm or 0.6mm galvanized sheet |

|

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

|

(1) Simple Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet | |

| Door | Simple steel rolling shutter (within 10m2) | |

| Window | Very few | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Africa, Middle-East, South America (no snow, wind load below 0.4kn/m2) | |

|

(2) Standard Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 24m, H -lower than 8m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door(within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Snow loading below 0.5kn,wind loading below 0.5kn/m2 | |

|

3) Coastal (high wind speed) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Coastal areas (snow loading below 0.7kn, wind load below 1.2kn/m2) | |

|

(4) Cold Region (heavy snow) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | EPS/rock wool/PU sandwich board |

| Wall | EPS/rock wool/PU sandwich board | |

| Door | PU foamed rolling door | |

| Window | Alu. Alloy, Hollow glass | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Cold regions such as Norway, Russian, North Canada, Finland, Iceland, Greenland, Sweden, etc. (snow loads below 3kn, wind load below 1KN/M2) | |

|

(5) Steel Structure Workshop with Crane (5T, 10T, 20T) |

||

| Main structure | Single span: L -shorter than 20m, H -lower than 10m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Snow 0.5kn, wind load below 0.5kn/m2 | |

| Name | steel structure hangar |

| Standard | GB |

| Main Material | |

| Main frame | Q 235 &Q345 |

| Bracing | Angel and round pipe |

| Purlin | C or Z section steel |

| Connection | Normal bolts and High strength bolt |

| Roof panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Wall panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Accessories | Skylight belts, Ventilators, Down pipe, Out gutter |

| Windows | Aluminum window/PVC sliding window |

| Doors | Sliding door;Rolling up door;Folding tip-up door;PVC door |

| Surface | Hot dip galvanize or Painted |

| Packing | Main frame packed in 40FT container, maintenance packed in 40HQ container |

| Main market | North America, South America, Eastern Europe, Southeast Asia, |

| Africa, Oceania, Mid East, Eastern Asia, Western Europe | |

|

Name |

Steel Structural |

|

|

Dimensions |

Length |

H beam:4000-15000mm |

|

Thickness: |

web plate:6-32mm wing plate:6-40mm |

|

|

Height |

200-1200mm |

|

|

Color |

according to customers |

|

|

|

|

|

|

Advantages |

1. design according to customers' requirements |

|

|

2. manufacture under complete quality control system---ISO9001 |

||

|

3. Fast construction and easy installation . |

||

|

4. installation with instruction of experienced engineers |

||

|

5. Hight quality and low-price . |

||

|

6. Wide span , Flexible design , Long using life |

||

|

7.Others: environmental protection, stable structure, earthquake resistance, water proofing, and energy conserving. |

||

|

Main components |

Main frame |

H beam |

|

Purlin |

C or Z section steel purlin |

|

|

Brace |

Anchor, ordinary, high strength bolt |

|

|

Bolt |

Sandwich panel or steel plate |

|

|

Roof &wall |

PVC or aluminum alloy door |

|

|

Door |

Sliding or rolling door |

|

|

Insulation panel |

EPS,XPS,Rock wool , PU sandwich |

|

|

Material |

Q235,Q345 China standard steel |

|

|

Sheet |

0.5mm or 0.6mm galvanized sheet |

|

Technical characteristics of containers type modules elements

(1)ISO standard dimensions of 20 feet STANDARD containers-optionally 10 up to 30 feet

(2)length=6.058 mm (optionally 3.048 - 9.100 mm)

width=2.438 mm (optionally 3.000 mm)

(3)exterior height=2.591 mm (optionally 2.791 mm or 3100 mm)

(4)inner height = 2.300 mm (optionally 2.500 mm or 2800 mm)

container construction difference

ZINCED metal profyles 3 mm connected with scres

container painting

(1)option: on customer wish in RAL color

(2)option: painted on customer wish in RAL color

container floor opening for forklift

(1)without forklift pockets

(2)option: with forklift pockets for containers up to 7.335 mm

(3)holes distance 1.506mm

container roof construction

container exterior wall and side panels

(1)50 mm poliurethane panel, externally micro-corrugated RAL 9002

internally smooth RAL 9010 (white)

(2)option: 60 mm mineral wool, both side plastificated in RAL 9002

(3)option: 60 mm mineral wool, both side plastificated in RAL 9002, internally enriched chipboard 100 WHITE010 (white)

(4)option: 80 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(5)option: 100 mm poliurethane panel, both side plasticated steel plate RAL 9010 (white)

(6)option: 100 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

(7)option: 120 mm mineral wool, both side plasticated steel plate RAL 9010 (white)

container exterior and inner walls

PVC with polyurethane filling 40 mm, clear opening 79/202 cm

container windows and doors

(1)option: windows without shutters

(2)option: windows with shutters

container isolation, coefficient of thermal resistance

floor - U = 0,37 W / m2k

roof - U = 0,39 W /m2k

wall panels - U = 0,41 W /m2k

windows - U = 2,40 W / m2k

Flat Pack Containerized Modular House Solution

Individual KXD container modules

They are assembled in KXD factory production from KXD manufactured elements. They come to the market as finished product as residential or office space equipped with or without equipment. Individual container modules are used as a single objects as bungalows, dormitories, offices, warehouses, shops, workshops and a built MODULE for the construction of various shapes and purposes.

dimensions and weights

container location preparation

container handling and lifting

option: Forklift for lifting containers up to 7.3 m in lenght if container has forklift holes

container electric installations

Illustration of singel module for multi-storey modular house

Insight into the modular house

Wide application for Containerized Modular House Solution:

Modular Houses may be used for long-term, temporary or permanent facilities, such as construction camps, schools and classrooms, civilian and military housing, and industrial facilities.[2] Modular buildings are used in remote and rural areas where conventional construction may not be reasonable or possible.Other uses have included churches, health care facilities, sales and retail offices, fast food restaurants and cruise ship construction. They can also be used in areas that have weather concerns, such as hurricanes.

Construction process for modular house

Modular components are typically constructed indoors on assembly lines. Modules' construction may take as little as ten days but more often one to three months. Completed modules are transported to the building site and assembled by a crane.[4] Placement of the modules may take from several hours to several days.

Manufacturing considerations

The entire process of modular construction places significance on the design stage. This is where practices such as Design for Manufacture and Assembly (DfMA) are used to ensure that assembly tolerances are controlled throughout manufacture and assembly on site. It is vital that there is enough allowance in the design to allow the assembly to take up any "slack" or misalignment of components. The use of advanced CAD systems, 3D printing and manufacturing control systems are important for modular construction to be successful.[5] This is quite unlike on-site construction where the tradesman can often make the part to suit any particular installation.

Advantages of modular house

Modular buildings are argued to have advantages over conventional buildings, for a variety of reasons.

Speed of construction/faster return on investment. Modular construction allows for the building and the site work to be completed simultaneously. According to some materials, this can reduce the overall completion schedule by as much as 50%.

Indoor construction. Assembly is independent of weather, which can increase work efficiency and avoids damaged building material.

Ability to service remote locations. Particularly in countries in which potential markets may be located far from industrial centers, such as Australia, there can be much higher costs to build a site-built house in a remote area or an area experiencing a construction boom such as mining towns.[citation needed]

Low waste. With the same plans being constantly built, the manufacturer has records of exactly what quantity of materials are needed for a given job. While waste from a site-built dwelling may typically fill several large dumpsters, construction of a modular dwelling generates much less waste.

Environmentally friendly construction process. Modular construction reduces waste and site disturbance compared to site-built structures.[citation needed]

Flexibility. One can continually add to a modular building, including creating high rises.[6]

Generally speaking, our Steel structure warehouse/workshop are categorized as below:

|

(1) Simple Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet | |

| Door | Simple steel rolling shutter (within 10m2) | |

| Window | Very few | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Africa, Middle-East, South America (no snow, wind load below 0.4kn/m2) | |

|

(2) Standard Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 24m, H -lower than 8m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door(within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Snow loading below 0.5kn,wind loading below 0.5kn/m2 | |

|

3) Coastal (high wind speed) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or 50mm EPS sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Coastal areas (snow loading below 0.7kn, wind load below 1.2kn/m2) | |

|

(4) Cold Region (heavy snow) Steel Structure Workshop |

||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | EPS/rock wool/PU sandwich board |

| Wall | EPS/rock wool/PU sandwich board | |

| Door | PU foamed rolling door | |

| Window | Alu. Alloy, Hollow glass | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Cold regions such as Norway, Russian, North Canada, Finland, Iceland, Greenland, Sweden, etc. (snow loads below 3kn, wind load below 1KN/M2) | |

|

(5) Steel Structure Workshop with Crane (5T, 10T, 20T) |

||

| Main structure | Single span: L -shorter than 20m, H -lower than 10m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Snow 0.5kn, wind load below 0.5kn/m2 | |

| Name | steel structure hangar |

| Standard | GB |

| Main Material | |

| Main frame | Q 235 &Q345 |

| Bracing | Angel and round pipe |

| Purlin | C or Z section steel |

| Connection | Normal bolts and High strength bolt |

| Roof panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Wall panel | Corrugated steel sheet or EPS, Glass wool, Rockwool, PU, etc sandwich panel |

| Accessories | Skylight belts, Ventilators, Down pipe, Out gutter |

| Windows | Aluminum window/PVC sliding window |

| Doors | Sliding door;Rolling up door;Folding tip-up door;PVC door |

| Surface | Hot dip galvanize or Painted |

| Packing | Main frame packed in 40FT container, maintenance packed in 40HQ container |

| Main market | North America, South America, Eastern Europe, Southeast Asia, |

| Africa, Oceania, Mid East, Eastern Asia, Western Europe | |

|

Name |

Steel Structural |

|

|

Dimensions |

Length |

H beam:4000-15000mm |

|

Thickness: |

web plate:6-32mm wing plate:6-40mm |

|

|

Height |

200-1200mm |

|

|

Color |

according to customers |

|

|

|

|

|

|

Advantages |

1. design according to customers' requirements |

|

|

2. manufacture under complete quality control system---ISO9001 |

||

|

3. Fast construction and easy installation . |

||

|

4. installation with instruction of experienced engineers |

||

|

5. Hight quality and low-price . |

||

|

6. Wide span , Flexible design , Long using life |

||

|

7.Others: environmental protection, stable structure, earthquake resistance, water proofing, and energy conserving. |

||

|

Main components |

Main frame |

H beam |

|

Purlin |

C or Z section steel purlin |

|

|

Brace |

Anchor, ordinary, high strength bolt |

|

|

Bolt |

Sandwich panel or steel plate |

|

|

Roof &wall |

PVC or aluminum alloy door |

|

|

Door |

Sliding or rolling door |

|

|

Insulation panel |

EPS,XPS,Rock wool , PU sandwich |

|

|

Material |

Q235,Q345 China standard steel |

|

|

Sheet |

0.5mm or 0.6mm galvanized sheet |

|

| Offer request | |||

| Type of sandwich panel |

|

||

| Dimension | length | thickness of core | thickness of steel sheet |

|

|

|

|

|

| Construction Site |

|

||

| Contact Name |

|

||

| Company Name |

|

||

| Phone Number |

|

||

|

|

|||

| Additional info |

|

||

| Send us sketches, drawings or the project, if you have | |||

Grupos de Producto : Panel sándwich de acero

Premium Related Products

Otros productos

Productos hot

Chalet de estructura de acero ligero en ÁfricaInsulated Prefabricated Building with Ce CertificationHoja de acero Corrugated Color (KXD-CSS1)Estructura de acero pintada C Sección Purlin (KXD-C2)Estructura de acero Casa de aves de corral / Casa de pollo (KXD-PCH2)Edificio de estructura de acero prefabricado para garaje y almacénCasa modular prefabricada del envase con la certificación del CeAlmacén de estructura de acero de almacenamiento de grano agrícola (KXD-pH9)Casa prefabricada de buen aislamiento para alojamientoPrefabricados de acero estructura taller edificio (KXD-SSW9)Modular prefabricado construcción móvil para diversos finesEstructura de estructura de acero prefabricada Warehouse (KXD-SSW5)Edificio de estructura de acero de luz prefabricados (KXD-SSB1)Estructura de acero prefabricó la casa móvil (KXD-PH8)Nave prefabricada de acero estructuralTaller prefabricado de acero estructural